.jpg?auto=compress%2Cformat&height=300&width=555&trim=color&trimcolor=FFFFFF&trimTol=15&ixlib=csharp-3.2.1.0&s=1c55e62d65aa67fe7234b9e089d76c89)

.jpg)

.jpg?auto=compress%2Cformat&height=300&width=555&trim=color&trimcolor=FFFFFF&trimTol=15&ixlib=csharp-3.2.1.0&s=1c55e62d65aa67fe7234b9e089d76c89)

.jpg)

1 pieces in stock at Vaughan, ON as of 2:32 AM. Directions. Call: (289) 474-5447

9 pieces in stock at Mississauga, ON as of 2:32 AM. Directions. Call: (289) 562-1077

| Attribute | Value |

|---|---|

| Contents | 400 ml |

| Description | Zinc Spray Perfect |

| Chemical basis | Alkyd resin |

| Pure Zinc | 99% |

| Cross Cutting (DIN 53151) | Gt0-1 |

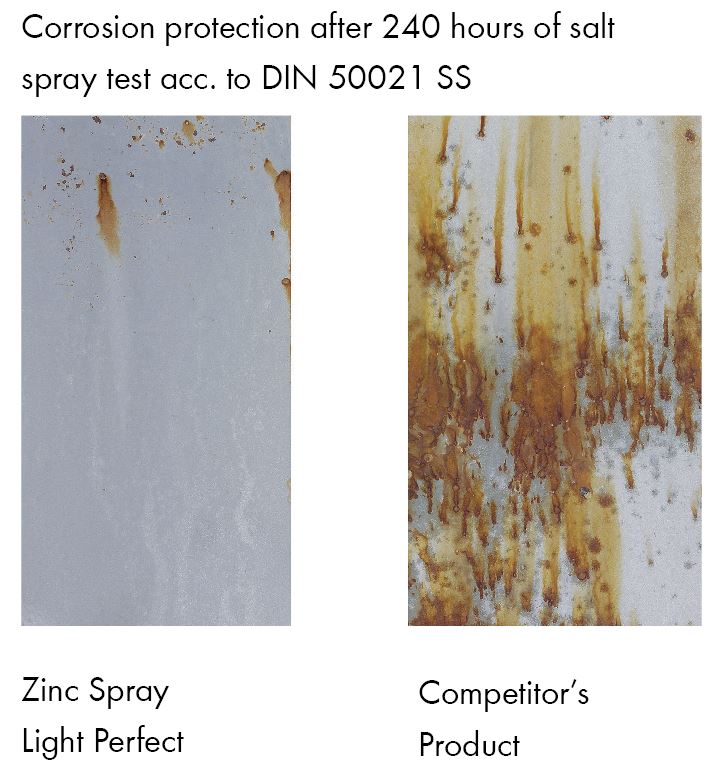

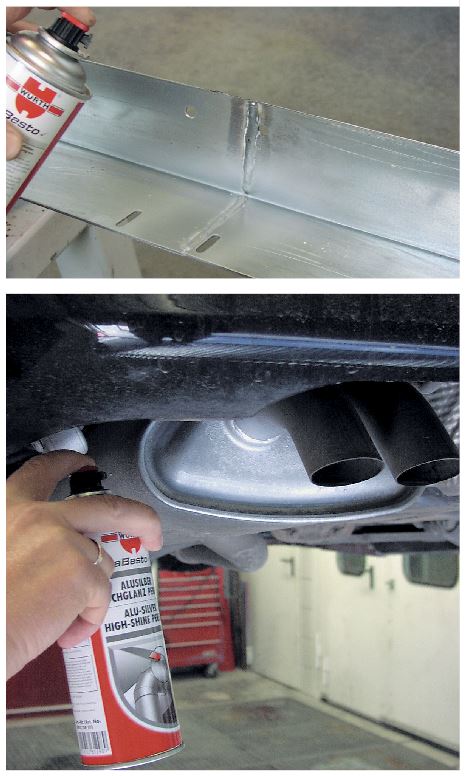

| Salt Spray Test (DIN 50021 SS) | 500 hrs |

| Dry Layer Thickness | approx. 40 μm |

| Recommended Layer Thickness | 40 μm |

| Dust-dry (with recommended dry layer thickness) | 5 min. |

| Completely Hardened (with recommended dry layer th | 60 min. |

| Touch-dry (with recommended dry layer thickness) | 18 min. |

| Can Be Spot Welded | Yes |

| Thermal Stability | approx. +500 °C (+932 °F) |

| Minimum Shelf Life At +10 °C to +25 °C (+50 °F to | 24 |

| Surfaces With Good Adhesion | Steel, Galvanized steel |

| EAN | 4045989594771 |

| High layer thickness in 1st spray pass. |

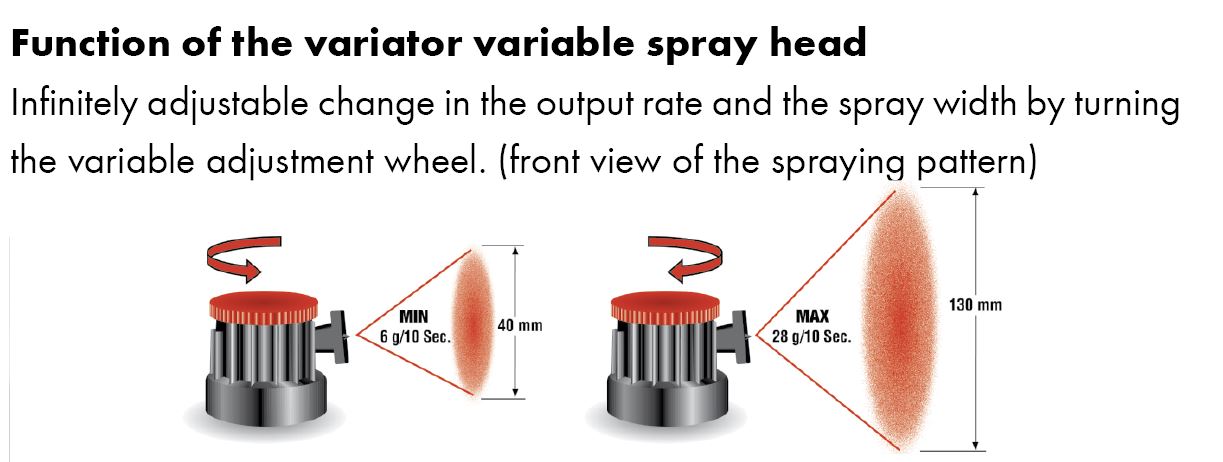

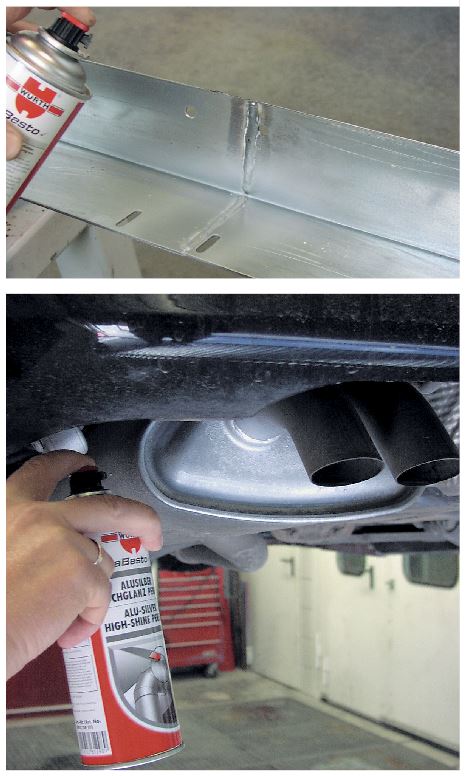

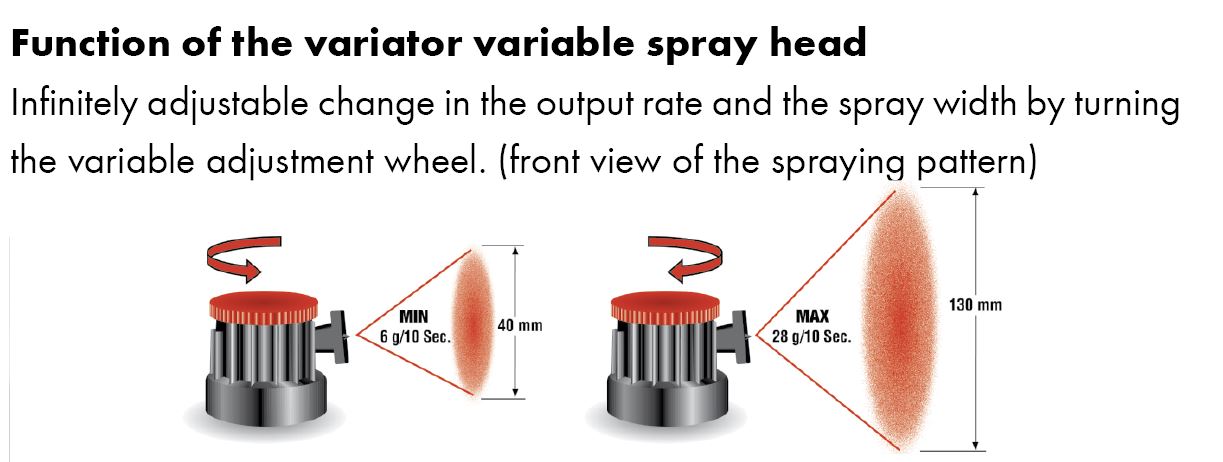

| Can be used on residual rust. |

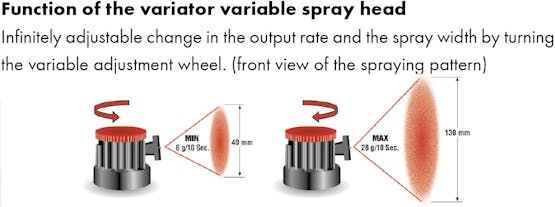

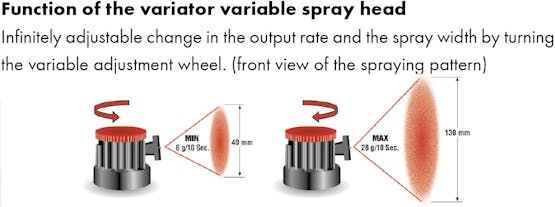

| For variable use thanks to adjustable spray head. |

| High resistance to running. |

| High abrasion resistance. |

| Very safe due to optimal protection against weathering. |

| Minimal time required, as only one work step necessary. |

| Covers well. |

| Only loose rust must be removed. |

| Large-area and minor repairs can be carried out quickly and safely with the variable spray head. |