3 pieces in stock at Vaughan, ON as of 7:48 AM. Directions. Call: (289) 474-5447

1 pieces in stock at Mississauga, ON as of 7:48 AM. Directions. Call: (289) 562-1077

| Attribute | Value |

|---|---|

| Contents | 2 x 89 ml |

| Mixing Ratio | Component A: Component B = 1:1 |

| Initial Setting Time | 7-12 min. (room temperature) |

| Full Hardening Time | 4-24 h (room temperature) |

| Pot Life | 5 min. / 20 g (room temperature) |

| Consistency | Cannot run down |

| Spec. Gravity | 2.80 with Components A and B mixed |

| Compressive Strength | 70 N/mm2 |

| Tensile Strength | 12.5 N/mm2 |

| Shear Tensile Strength | 14.5 N/mm2 |

| Thermal Stability | 0.7 Kcal/mh°C, -60°C to +120°C |

| Dimensional Stability / Martens | +40°C |

| Coefficient of Thermal Expansion | +40x10-61°C |

| Malleable | up to +120oC/1h |

| Storage Stability | Min. 2 years |

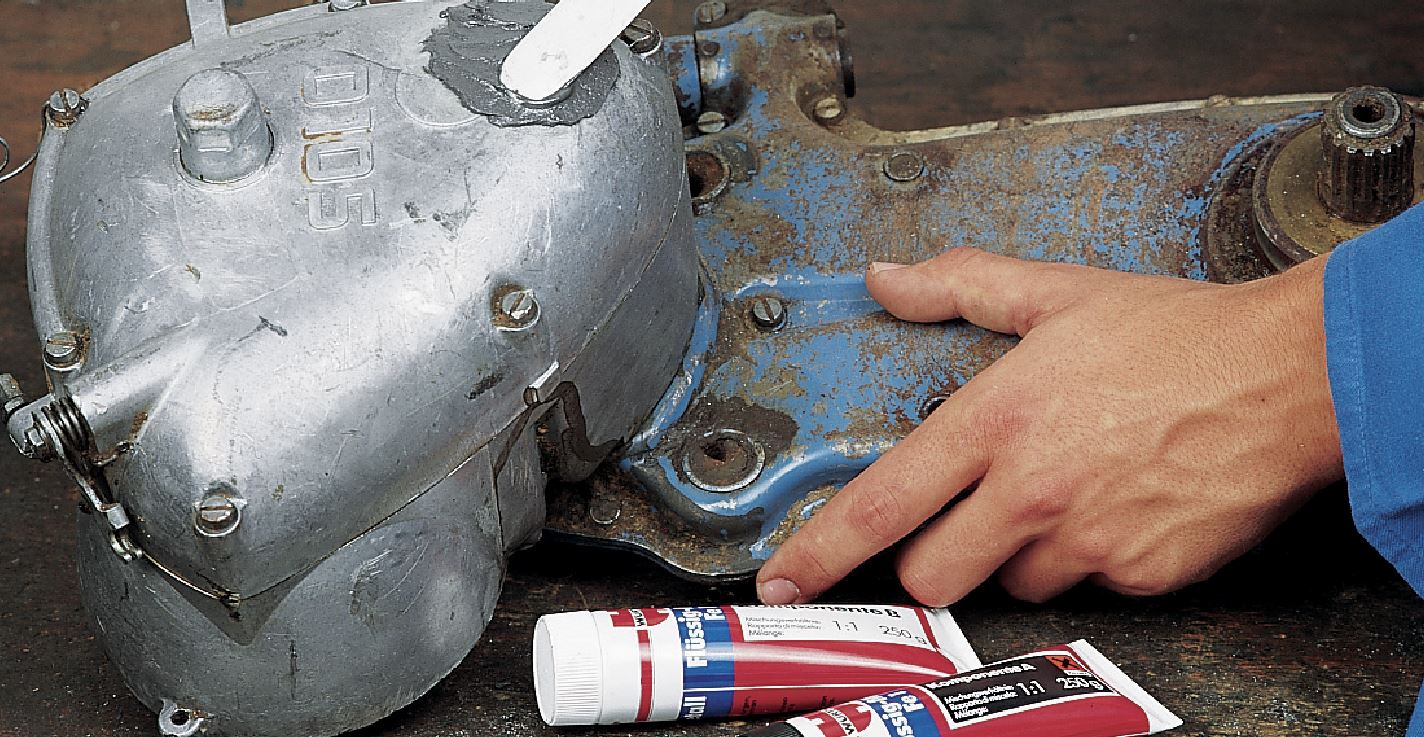

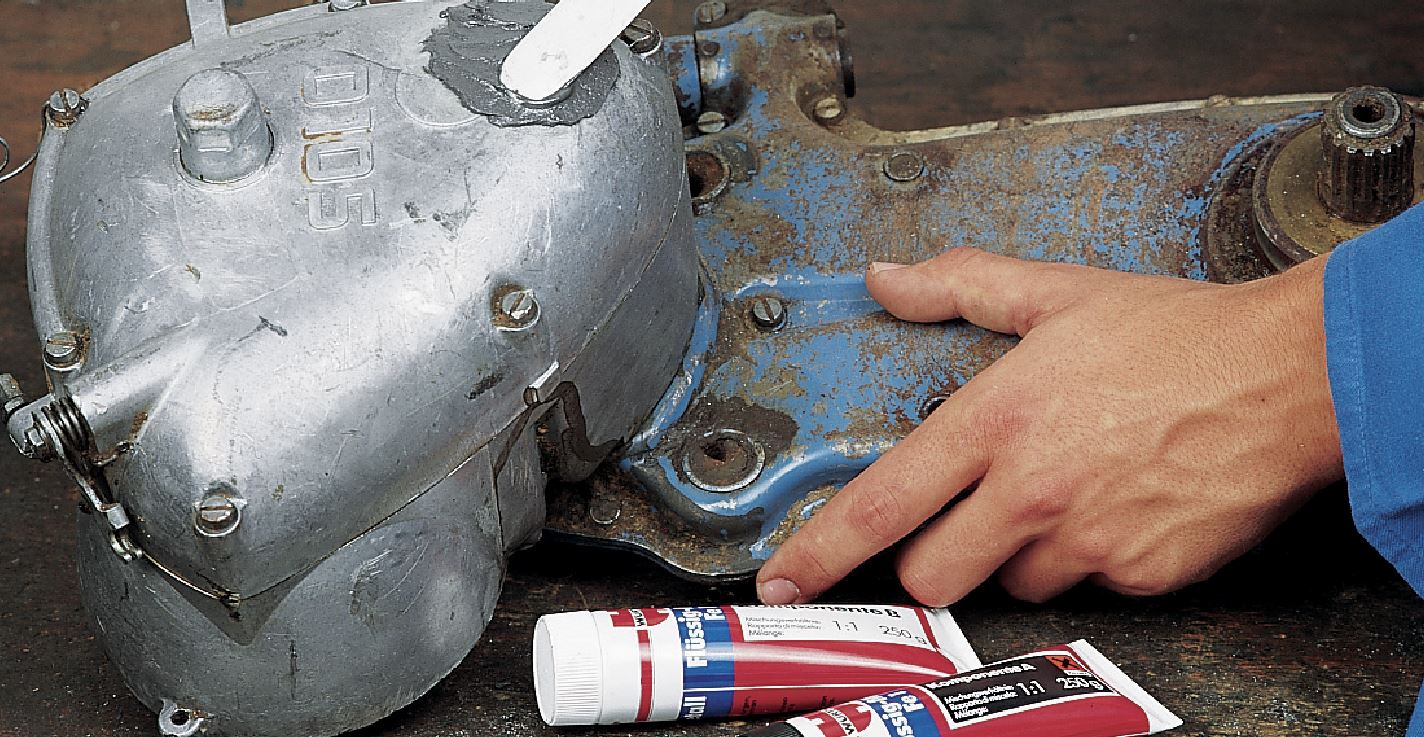

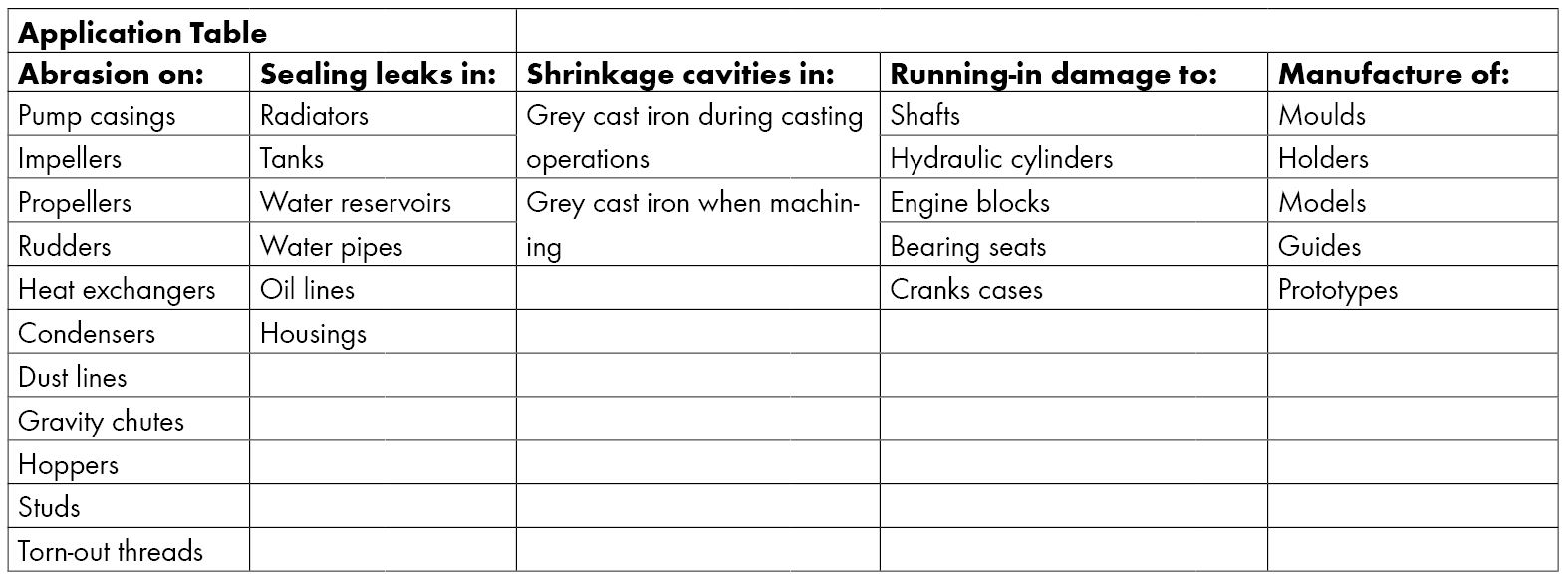

| Fe 1 is a high grade, two-component reaction resin system which is formulated specifically to obtain metalline characteristics |

| The ideal mixing ratio of the components (A:B = 1:1; press two strands of equal length out of the tubes) makes it practically impossible to mix the repair compound incorrectly |

| Fe 1 is specifically designed for small repair jobs which must be performed quickly |

| Fe 1 can be applied with a spatula without it running down, so it can also be used for work on a vertical plane |

| After hardening, Liquid Metal Fe 1 can be machined like metal without difficulty by turning, milling, drilling, filling or thread cutting |

Product not yet rated.