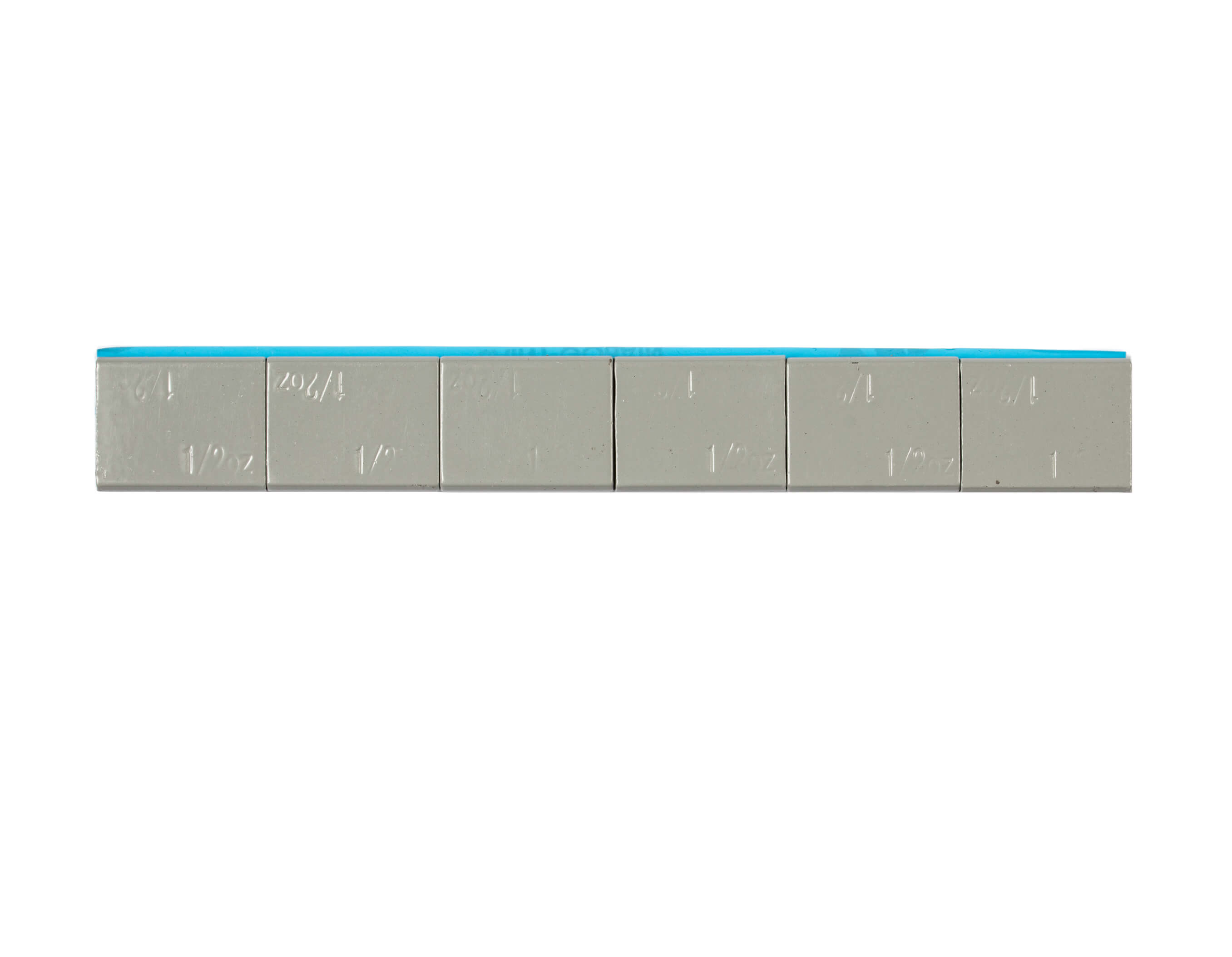

WHL WHT ADH-N FE GRY 6X1/2OZ-3OZ

830.905150

- UNSPSC 25191701

0830905150961 48

0830905150961 48

Delivery

0 Review(s)

Units/package: 48

IN-STORE

(Live stock shown is only for our stores located in Ontario.)

Temporarily out of stock in Vaughan, ON and Mississauga, ON as of 6:00 PM.

Product Details

| Attribute | Value |

|---|---|

| Type | 6 x 1/2 oz individual segments on a strip, 3 oz total weight |

| Material | Steel |

| Segment Weight | 1/2 oz |

| Segment Width | 24 mm |

| Segment Length | 19 mm |

| Segment Thickness | 4.5 mm |

| Strip Adhesive | Premium Cold Weather |

| Segment Coating | Grey |

| EAN | 4056807065922 |

Instructions

Adhesive wheel weights - Importance of pressure

• All adhesive wheel weights are made with Pressure Sensitive Adhesive (PSA)

• PSA’s require PRESSURE to “wet out” and activate the adhesive and provide a good bond.

• Even, perpendicular, pressure (about 5 psi) should be applied to the entire length of the weight, for 2-3 seconds

Adhesive wheel weights – best practices

• Clean

• IPA Surface Prep (893.223500) - Evaporates easily, removes condensation in winter

• Cloths should be turned/replaced frequently to avoid recontamination

• Surface Preparation!

• Contamination from dust, oil, dirty hands, tire lube, will affect adhesive performance

• In extreme cases, the surface can be roughened with a mild abrasive (Fibratex)

• Wait!

• Make sure your chemical cleaner has evaporated fully before applying the weight

Adhesive wheel weights – diagnosing problems

• Adhesion Test:

1. Stick some weight segments to a clean piece of glass.

2. Let cure for a few minutes.

3. Check adhesion. If the weight sticks, the adhesive is not the problem.

• The usual cause? Application!

• Improper cleaning & chemicals (Brake Clean, Buffing Solution, etc. can leave

residues behind)

• Lack of application pressure

• Contaminated adhesive

• Temperature (Cold wheels or tape cause adhesion problems)

• Any combination of the above.

Customers Also Viewed

Review(s)

Product not yet rated.